Software

ENVision

Organisations need to increase their agility and stay price-competitive in the shorter term and build the ‘factory’, asset or production operations of the future to stay relevant and continue to compete. However, operations, planning, and resourcing tools are often not fit for purpose, leading to downtime, excessive redundancy, budgets tied up in ‘keeping the lights on’ versus innovation, and challenges to the development and delivery of new offerings.

Adoption of piecemeal solutions has created complexity versus clarity and the delivery of improvement. In-house teams often lack specialist technical skills, and external IT firms don’t have the industry knowledge to address specific industry requirements.

This leaves many organisations unsure of where to start, while others want to understand what their next steps should be to optimize and build on what they’ve achieved already. In both cases they need to consider what new solutions to invest in, how to manage obsolescence of legacy systems, how to integrate critical bespoke systems, and how to enable such extensive change. Operational transformation is key to navigate disparate, complex legacy and bespoke systems and vast volumes of data, to get the information and insight required to enable continuous performance optimization.

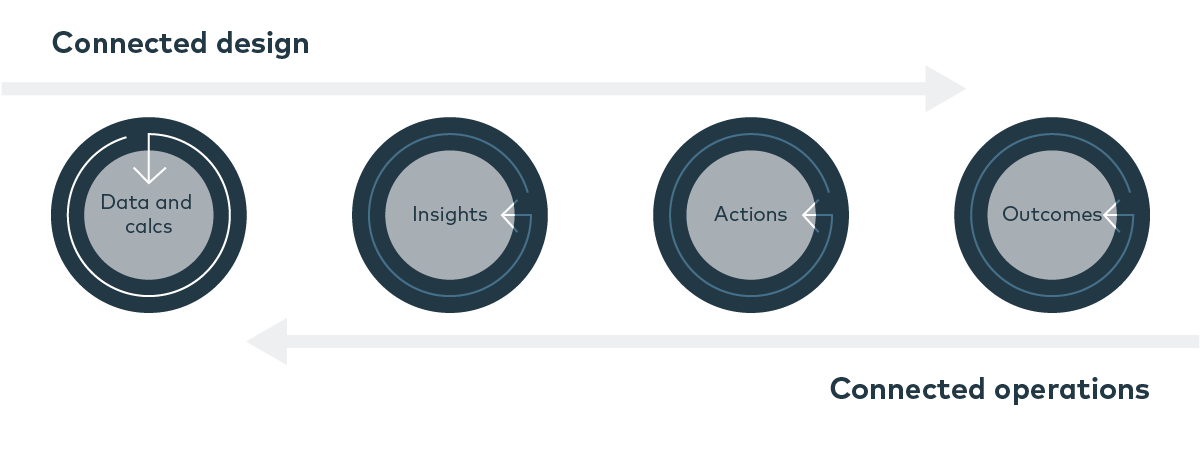

Wood’s Applied Intelligence team uses an agile, iterative, and proven methodology to accelerate time to value for operational transformation. We can deploy new digital process technology solutions and enhance connected operations across sectors. Solutions are designed to be future-ready that address clients’ immediate needs and help achieve operational excellence and optimized costs. An approach of starting ‘small’ and creating a roadmap for incremental operational change now helps clients reap the benefits of new innovations quickly, without significant disruption to operations or business. Our consulting expertise include dynamic simulation and analysis of systems from design through to operations.

By leveraging artificial intelligence effectively into operations and assessing and advising on system transformation where required to address issues and resolve interoperability challenges, Wood transforms data into actionable insights. This helps clients reconcile conflicting priorities and identify where they can improve quality, efficiency, and overall cost. We are always investing in proprietary technology solutions for operations that are delivered through cloud, making it robust and scalable, allowing real-time data acquisition, analytics, optimisation and control.

At Wood, we also have an established and strategic partner ecosystem with industry leaders and disruptors, including Microsoft, Cognite and AspenTech, to provide right-fit solutions that address clients’ specific challenges, with optimised configuration, implementation and production.

And finally, our consultative approach and human factors engineering, supports the organisation through operational change to ease adoption and reduce resistance to change.

Feature story

A consortium led by Nova Innovation, in collaboration with 11 other organisations including Wood, has spearheaded a European project that will use AI to transform the efficiency of tidal-energy generation. The €5 million ELEMENT project will incorporate state-of-the-art AI technology from wind energy into tidal turbines to deliver an adaptive control system that improves turbine performance, slashing the lifetime cost of energy by 17% and driving the tidal energy sector to commercial reality.

Feature story

By simulating a new CO2 injection process Wood is helping one of the world’s largest natural gas projects reduce its carbon emissions.

Based on our field-proven Virtuoso digital suite we have developed a flow management tool to help monitor the integrity of the system and manage the injection process of the Co2 injection plant that handles 40% of the total projected emissions for the client. We delivered a specialised offline and online simulator package for the operation, deploying a thermodynamic model, based on the Grand Unified Thermodynamic Simulator (GUTS) technology that improved the thermo-physical property predictions of CO2/water systems, and accounted for the effects of contaminants and impurities in the stream.

Feature story

We are the main automation contractor (MAC) on the TengizChevroil Future Growth Project FGP). FGP is one of the largest automation projects ever executed and it includes over 87,000 hardwired I/O and 65 remote instrument enclosures (RIEs). The project is being executed by Wood in the UK, Houston, Korea, Italy and Kazakhstan.

Empowering organisations to navigate the changing technology landscape

Pressure to transform both business and operations through digital innovation

Organisations must ensure sustained safety of the plant, planet and people